|

| January 19, 2016 | Volume 12 Issue 03 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

Military's sophisticated simulations help provide improved weapons faster, cheaper

By Ed Lopez and Cassandra Mainiero, Picatinny Arsenal, New Jersey

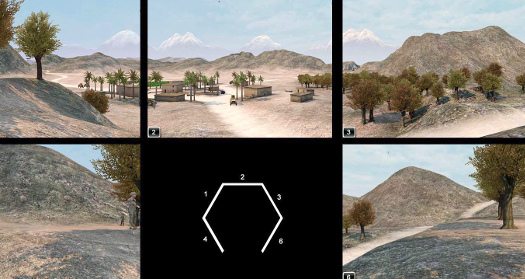

Cameras and computers behind screens at Picatinny Arsenal display various scenarios that provide engineers with critical information useful for faster weapons development.

As engineers design new weapons or modify existing ones, reducing time and money on development can be critical to providing Soldiers with improved weapons without undue delay.

A new sight may be planned for the M4 rifle, but how well does a prototype design work, and where would the best place be to mount it for the highest accuracy and most ease of use? Or new, non-lethal weapons may be needed, but will they perform as expected at different ranges?

Using a combination of artificial intelligence, cameras, and computers loaded with ballistics data, engineers at Picatinny Arsenal in New Jersey have developed a testing environment that can help to answer many critical questions about the performance of existing weapons and new ones planned.

"People are surprised how realistic our simulated environments look," said Keith Koehler, a mechanical engineer at the Weapons Technology Branch, part of the Weapons Software Engineering Center. "We had a few friends, who were deployed Soldiers, walk into the scenarios, and you could tell to a degree that they lost themselves in the environment."

The Simulated Weapon Environment Testbed, called SWeET for short, can project custom interior and outdoor scenarios for weapons evaluation. It can also project any weather (rain, snow, sunny, foggy, etc.), location (indoor, outdoor, towns, cities, rooms, jungle, etc.), or time of day onto its five screens, allowing up to four users per screen.

While it can take a few weeks to program new environments into the software, gathering data is instantaneous and records details such as target response, user response, reaction time, and target distance during each simulation.

SWeET works with unmodified weapons -- only bolts and magazines are swapped. Compressed air or CO2 is used to simulate recoil.

Weapons that can be currently tested in SWeET are the M4, M11, M9, M16, M249, M240, and weapon accessories. With five cameras and computers behind the screens that display simulated scenarios -- and a sixth computer that controls them all -- realistic projectile ballistics and travel/impact effects are captured.

Other cameras, placed above the five screens that project a 300-degree view, can monitor a Soldier's movements and reactions during the various scenarios.

Five screens can display a 300-degree view of realistic scenarios, which can be customized to meet the specific needs of individual projects.

A major advantage of SWeET is that, because it can capture vast amounts of data with prototypes of new weapons, the costs related to manufacturing multiple weapons during the development phase can be greatly reduced.

"Users can come here and test a weapon or the new ammunition before it is even made," said Clinton Fischer, a mechanical engineer, also with the Weapons Technology Branch. "In traditional development, they would have to first manufacture the weapon or the ammunition for it, and because there is no production line for it, it could be a thousand dollars a round. ... Here, we just make it, shoot, and get data."

However, because SWeET projects virtual environments onto two-dimensional screens, Fischer and Koehler also note that scope (or depth) can sometimes be difficult to mimic.

In addition, though testing the weapon's recoil is safer with SWeET than other testing systems, the recoil simulation is only about 90 percent accurate. Still, overall feedback on SWeET, with its speedy data output and realism, remains positive.

"We had some Soldiers come in and verify that our ranges were accurate," said Koehler. "We would pull up a target at 348 meters and ask, 'How far away did this guy look to you?' and they say, '350 meters.' So, even we didn't expect that kind of realism."

(From left) Picatinny Arsenal engineers Keith Koehler, Clint Fischer, and James Snover have worked on the Simulated Weapon Environment Testbed (SWeET) project, which uses a combination of artificial intelligence and sophisticated computer-data capture to reduce the time and cost associated with developing or modifying weapons systems. [Photo Credit: Erin Usawicz]

In the future, Fischer and Koehler plan to add new simulated weapons to the test bed, such as the M2 heavy-barrel machine gun and the Mk19 grenade machine gun.

"There are lots of simulators out there, but they're limited in their capability, and each one is made to train a specific situation," Koehler said. "One may train how you work in a squad; another is how to train your weapon, or something else. There are simulators for research and development to get information, but they are also limited. With SWeET, we're trying to take all those types of simulations and combine them. I don't think there is anything out there yet that can test all these capabilities."

Published January 2016

Rate this article

View our terms of use and privacy policy